Electrical Insulation

The right insulation can bring your components to the next level

Excellent

electrical

insulation

electrical

insulation

Flame

retardant

properties

retardant

properties

Protection

against dust

and moisture

against dust

and moisture

Increased

durability

Improved

mechanical

properties

mechanical

properties

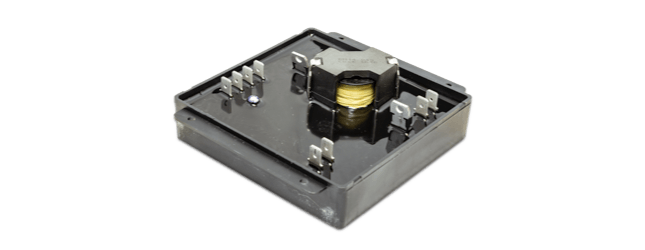

Electrical Insulation Applications

Igniters

Submersible Pumps

Ignition Coils

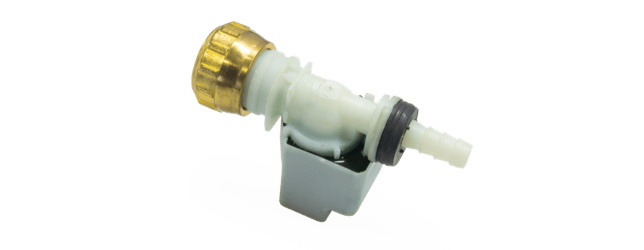

Aqua Stop Valve

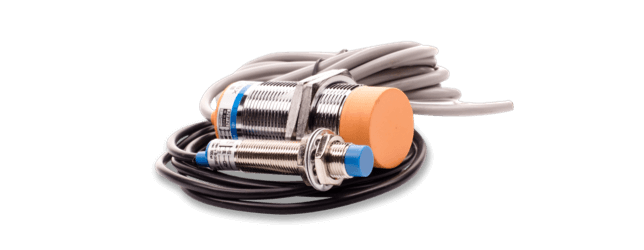

Sensors

Transformers

Capacitors

Electric Motors

PCBs

We proudly supply

Free ebook

Electrical insulation

without limits

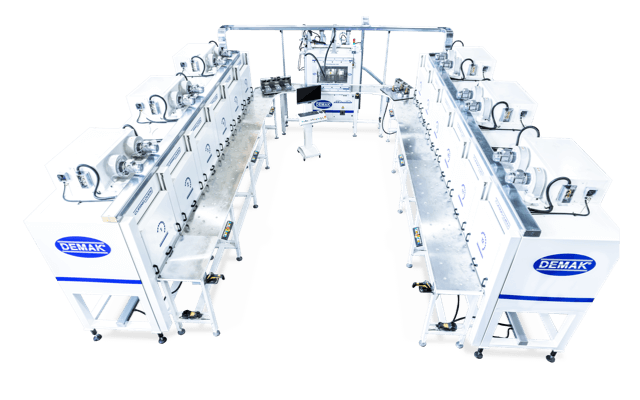

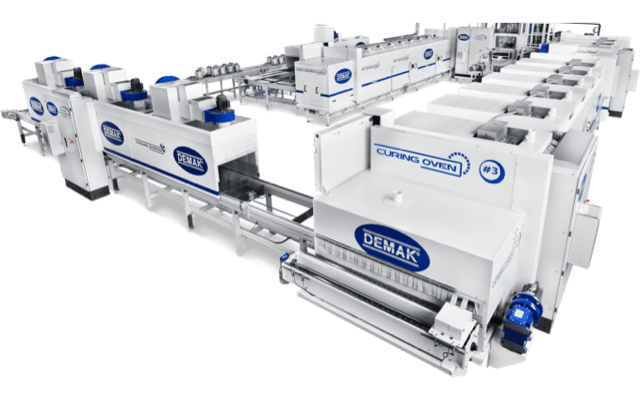

Dispensing Equipment for Electrical Insulation

Resin Systems

Demak Polymers: formulating, manufacturing and much more

Select the most suitable resin

Chemical

and humidity

resistance

and humidity

resistance

Low viscosity

and excellent

impregnation

Thermal shock

& cycles

resistance

& cycles

resistance

No waste,

lower

emissions

lower

emissions

Flame

retardant

properties

retardant

properties

Vibrations

and noise

reduction

and noise

reduction

High

Thermal

Dissipation

Thermal

Dissipation

High

operating

temperature

operating

temperature

Excellent

electrical

insulation

electrical

insulation

Main Resins Overview Electrical Insulation

RT EPOXY

XE 661 HV + DK 50_06

XE 661 + DK 50_06

XE 661 LV + DK 50_06

XE 661 HV + DK 50_06

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| 155 | 64 | 1,4 | V0 |

XE 661 + DK 50_06

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| 155 | 64 | 1,2 | V0 (4 mm) |

XE 661 LV + DK 50_06

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| 155 | 64 | 1,0 | V0 (4 mm) |

HEAT CURING EPOXY

XE 233 FR E + DK 442

XE 233 FR + DK 441

XE 201+ DK 432

XE 233 FR E + DK 442

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| 180 | 40 | 1,1 | V0 |

XE 233 FR + DK 441

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| 180 | 0 | 0,8 | V0 |

XE 201+ DK 432

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| 180 | 118 | 0,75 | V0 3mm |

POLYURETHANES

XP 116 FR + DK 001

XP 150 FR + DK 001

SEPUR 121 FR + DK 001

XP 116 FR + DK 001

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| -40/+130 | -20/-15 | 0,65 | V0 |

XP 150 FR + DK 001

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| -40/+130 | 15/20 | 0,8 | V0 UL94 1.5 mm |

SEPUR 121 FR + DK 001

| Applications | Operating Temperature °C | Thermal Glass Transition °C | Thermal Conductivity W/m.K | Flammability UL 94 |

|---|---|---|---|---|

| -40/+130 | 70/75 | 0,7 | V0 |

Potting Lab

A complete laboratory dedicated to perform tests together

DEMAK Full Cycle Consulting Approach

Process consulting

Chemical consulting

Design consulting

Time to get in contact?

Describe your needs

You’ll be contacted soon by our experts